This was originally produced by mechanical means using a stamp mill to create flakes. Subsequently, a process of spraying molten aluminium to create a powder of droplets was developed by Arun Patil in 1996. The resulting powder might then be processed further in a ball mill to flatten it into flakes for use as a coating or pigment.

Aluminium powder, if breathed in, is not particularly harmful and will only cause minor irritation. The melting point of aluminium powder is 660 °C.

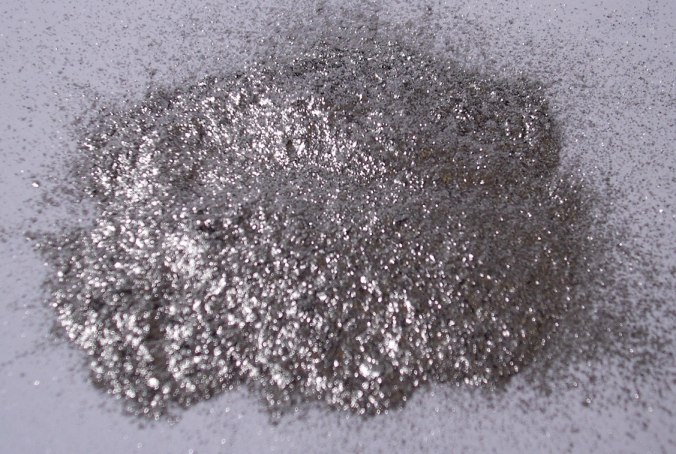

Aluminium powder, also known as aluminium flake or metana, is a light, silvery-white to grey, odourless, granular powder having flammable reactive properties. It is used for several applications such as manufacture of slurry, explosive and detonators, thermit process used for manufacture of ferro-alloys, specialised welding applications, and manufacture of aluminium paste, paints and several pigments used in automobiles manufacturing. There are four major grades of aluminium powder: Reagent grade, Technical grade, Bio-tech grade, and Analytical grade. In foundry, the metal powder is used as deoxidant and exothermic tapping compounds to increase the yield of casting.