A Low Profile Separator offers high capacities of wet or dry scalping in a low headroom design. The low profile separator has a single vertically mounted motor to generate a sifting motion across the screen plane.

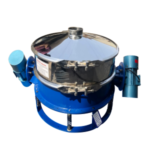

Inline Vibro Screen

an iso certified company 9001:2015

A INLINE VIBRO SCREEN MACHINE IS IMPROVE YOUR

PRODUCTION THROUGH OUT.

We Are Offering

Inline Viro Screen

Specification Of Inline Vibro Screen

this sifter works on two imbalanced-weight gyratory motors mounted on opposing exterior sidewalls of the unit, instead of one motor positioned beneath the screening chamber, reducing overall height significantly. The design also allows vertical alignment of the top inlet and bottom outlet, allowing on-size material to descend through the screen in a straight-through path at high rates. Oversize material is ejected through a spout at the periphery of the screen.

Delite can provide you the customized solution as per your need. Delite serves gyro screen to you with add-on equipment like vibrasonic deblinding system, clamping system, castor wheel for plant movement and many more to ease and please your screening operation.

The main advantage of the Inline vibro screener equipment lies in its acute design. Feeding inlet & material discharge outlet in the same centreline helps in reduction of screening time by reducing the movement of the material inside the sifter. Extracting the previous line, we can say it’s a low headroom gyratory screener for higher capacity & better efficiency.

FEATURES OF Inline Vibro Screen

Low Headroom

Inline Sifter provides low headroom design which easily fits into the existing process line.

Center In - Center Out

Feeding inlet & material discharge outlet in the same centreline helps in reduction of screening time.

Mobility

Castor wheels are provided for easy in-plant movement .Mobility is the ability to move freely.

Quick Screen Change

Changing the screen ring is quicker because of the easy clamping set.

60

Industry Served

50+

Team Members

550

Happy Clients

1000+

Projects Done

BENEFITS OF Inline Vibro Screen

LOW MAINTENANCE

Inline vibro scrren does not require regular maintenance. As a result, the cost of maintenance is reduced.

LOW MANPOWER

The machine runs smoothly for a long time without any interruption. Therefore, low manpower is needed.

HIGH THROUGHPUT

Due to its center in – center out construction it reduces the movement of the material inside the sifter and hence increases throughput capacity.

Our Products Gallery