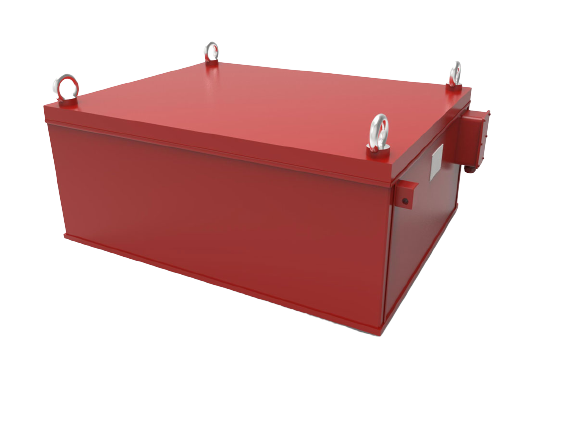

The suspended magnets are designed exclusively for removal of infrequent tramp iron from material being accepted by conveyor belt, vibratory feeder or gravity chute. The Suspension Magnet is suspended over the material being conveyed.

Suspension Magnet

an iso certified company 9001:2015

A SUSPENSION MAGNET IS DEVELOP YOUR

PRODUCTION THROUGH OUT.

We Are Offering

Suspension Magnet

Specification Of Suspension Magnet

Suspended Permanent Magnets use ceramic magnetic material arranged in a very specific pattern to create a powerful magnetic field. Each model is designed for the application based on conveyor width and speed, material burden depth as well as the density or frequency of tramp iron present in the process.

Electromagnetic suspension is the magnetic levitation of an object achieved by constantly altering the strength of a magnetic field produced by electromagnets using a feedback loop. The application of magnetic levitation is most commonly known for its role in Maglev trains.

Delite magnetics suspension type magnets are mainly useful for products carried by the conveyor belt. Use of suspension type magnet is recommended for products with low contamination. If the frequency of the impurities is too high, suspension type magnet will make a layer shunting magnetic field. It will require frequent cleaning.

FEATURES OF Suspension Magnet

Permanent magnet field

Permanent ferrite suspended magnets (block magnets) devour no energy, which is one of the elements that makes them so rate effective. These magnets eliminate ferromagnetic particles as small as 0.5 mm.

Heavy duty impact plate

These heavy duty electro flux suspension magnet incorporation all welded, duty impact plate stainless steel angled cleats options, Heavy duty impact plate on magnet face. Structural steel channel frame.

Stainless steel angled cleats

As the ferrous metal is attracted to the magnet, the cleats on the magnet's belt move and long angle, pipe or bars can cut, abrade, puncture, or rip the magnet's and armor clad belts.

Compact design

Suspension magnets are designed to extract tramp iron from the product, of small ferrous contaminants such as nails and screws. This magnets are designed for high separation.

60

Industry Served

50+

Team Members

550

Happy Clients

1000+

Projects Done

BENEFITS OF Suspension Magnet

No need for power supply

Is ideal for applications that require increased suspension heights for the magnet. Suspended Overhead Magnets. Required. Power Supply. Suspended magnets are widely used to remove damaging tramp metals.

No breakdown

Unlike conventional bar magnets, there is no magnetic pole gap with respect to the flow direction of raw. It is suspended in the range of 1 to 10 mm, and it adsorbs magnetic metal. Maintenance-free, No breakdowns or malfunctions.

No maintenance

STANDARD PERMANENT SUSPENDED MAGNETS. Easy to clean and no maintenance cost and preventing expensive shutdown. Maintenance procedures for these magnets are detailed in the text.

Our Products Gallery