The Delite Tumbler Screen generates three-dimensional tumbling motion (elliptical movement) that enables screening of fine & ultra-fine particles with ease. The elliptical movement sets radial & tangential inclination. The screening material spreads evenly on the entire surface from the centre towards the periphery.

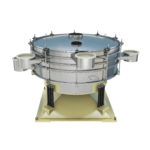

Tumbler Screen

an iso certified company 9001:2015

A TUMBLER SCREEN MACHINE TO INCREASE YOUR

PRODUCTION THROUGH OUT.

We Are Offering

Tumbler Screen

Specification Of Tumbler Screen

The elliptical movement sets radial & tangential inclination. The screening material spreads evenly on the entire surface from the centre towards the periphery. The radical inclination makes the screening material move from center to outwards & tangential inclination makes material move in a circular pattern, thus a spiral motion is achieved. Fine particles pass through from center while coarse particles travel outwards in a circular pattern on periphery & are discharged from the outlet.

It is best suitable for screening low bulk density products like talc powder, grading & sorting granules, light-weighted & ultra-fine particles. The proven record stands for screening & sorting requirements of food & beverage, pharmaceutical, minerals & metallurgy, plastic, & chemical industry. Delite Tumbler Screen is well structured to deliver optimal efficiency & best results for high bulk density products & any applications/materials regardless of their characteristics. To meet the requirement of highly sensitive industries such as food, pharmaceuticals & chemical we offer the machine in the highest standards. Tumbler screener is available as per GMP & FDA guidelines with extremely smooth surface & crevice-free joints. On-demand, the whole tumbler machine could be exclusively manufactured with 304, 316 or 316L grade of stainless steel.

The robust designed Delite Tumbler screen is a real-time solution for products having low bulk density & where very fine particles to be separated from the larger ones. It can deliver optimal results for high BD products as well.The Delite Tumbler Screen generates three-dimensional tumbling motion (elliptical movement) that enables screening of fine & ultra-fine particles with ease.

FEATURES OF Tumbler Screen

Enclosed System

Totally enclosed design that enables dust-free operation & worker's and engineesafety while operating hazardous materials.

Pneumatic Deck Lifting System

To ease the process of cleaning, maintenance & screen changing, we provide Tumbler screen with pneumatic lifting arrangement.

Fractionable up to 6 grades

The Delite Tumbler Screen can be opted with 5 decks to achieve 6 levels of grades for any of your product or material.

Controlled Noise Level

Delite Tumbler Screen is quite & has less noise level as compared to conventional Vibro sifters. Noise level is less than 75DB.

60

Industry Served

50+

Team Members

550

Happy Clients

1000+

Projects Done

BENEFITS OF Tumbler Screen

HIGHER EFFICIENCY & ACCURACY

The three-dimensional tumbling motion helps to achieve 99% higher efficiency while screening or accuracy while grading any material.

LONG LIFE SPAN

As compared to vibrating separators it has 3-4 times less acceleration, & due to that Tumbler screens have a longer life span.

ECONOMICAL SCREENER

The Delite Tumbler Screen consumes less electric power & also they require minimal maintenance as compared to Vibro screeners.

Our Products Gallery